The concept of numerically controlled machines dates back to the 1940s, when the military used analog computers to guide aircraft guns and torpedoes. By the 1950s, the first digital computer-controlled machine tools were developed, paving the way for early CNC machines. These early mills and lathes were expensive and limited, but they showed promise for automating manufacturing processes and improving accuracy.

Throughout the 1960s and 1970s, CNC technology continued to advance, with key developments such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These systems allowed engineers and designers to create more complex geometric shapes and designs, while CNC machines could produce these components more accurately and efficiently than ever before. By the 1980s, CNC machines had become essential tools in many industries, from aerospace and defense to automotive and electronics.

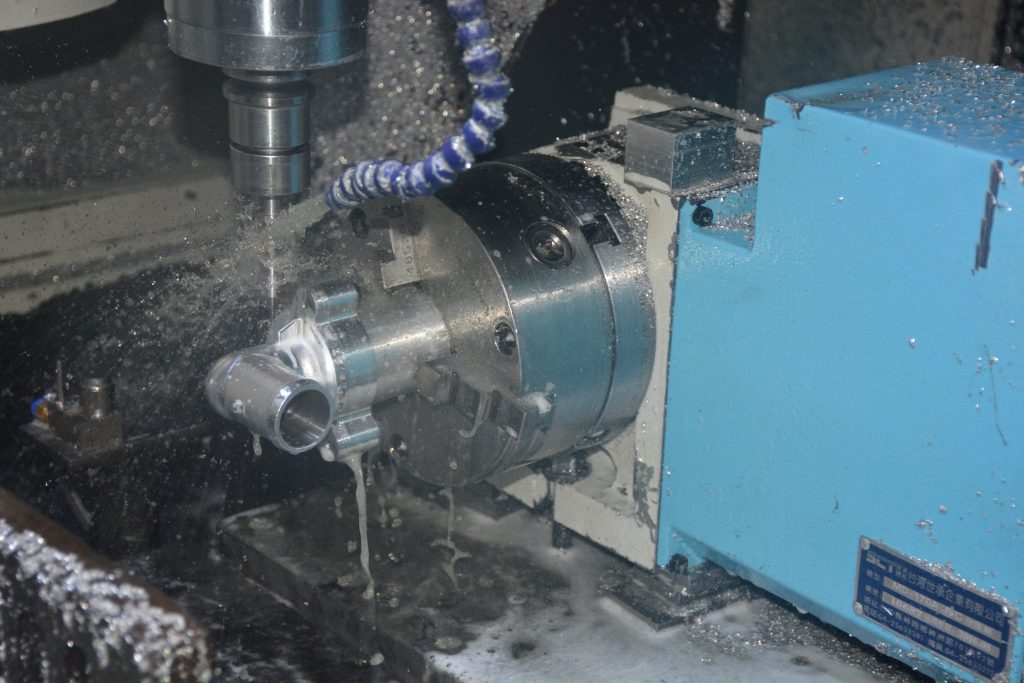

The 1990s saw significant advancements in CNC technology, particularly in the areas of automation and precision. CNC machines now featured robotic tool changers and pallet systems, allowing for continuous operation and increased output. High-speed spindles and 5-axis machining capabilities also enabled more complex parts and designs, with greater precision and accuracy than ever before.

In the 2000s, the integration of CNC with other technologies such as 3D printing and additive manufacturing further expanded the capabilities and applications of this technology. Today, CNC machines are used in a wide range of industries, from aerospace and medical devices to automotive and consumer electronics. They are also often combined with other technologies such as robotics and artificial intelligence, creating new opportunities for automation and innovation.

Conclusion:

The history of CNC machining is a testament to the power of innovation and progress in engineering and design. From early analog computers to the latest advances in robotics and automation, CNC machines have come a long way in a relatively short period of time. Today, they are among the most essential tools in modern manufacturing, enabling engineers and designers to realize their visions with unprecedented precision and efficiency. Whether you’re a mechanical engineer, buyer, or designer, understanding the history and evolution of CNC machining can help you leverage its full potential and stay ahead of the curve in your projects and products.