we specialize in manufacturing precision machined parts for the medical, automotive, research, and other industries. With over three generations of knowledge and experience, our team is able to produce parts that require innovative tooling and fixturing in a timely manner. We approach each job with the intention of minimizing the number of operations & run-time, therefore increasing accuracy & efficiency, and decreasing cost.

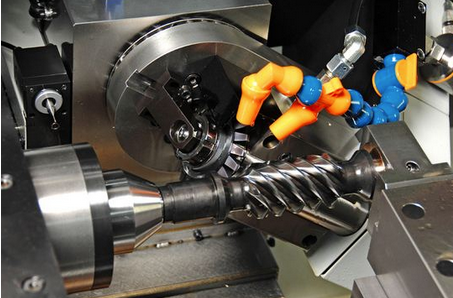

When tight tolerances, complex geometries, or production-grade materials are needed for your project, our in-house CNC machining service can achieve your desired results. Our skilled machinists use CAD/CAM technology to optimize your design files for quality, accuracy, and cost.

Our CNC service specialists can produce turned and milled parts, prototypes, and molds using virtually any plastic, metal, or composite material.

We have more than 30 sets CNC milling machines, can help you to

make prototype in 5-7 days. The maximum machining accuracy

can reach 0.05mm

MFG HUBS has more than 20 years of experience in CNC turning,

by using automated CNC machining and CAD/CAM software, we can

produce parts and threads that meet the drawing requirements.

5-axis CNC machining allows complex parts with multiple side features

to handle up to five sides in a single setup. MFG HUBS has the capability

of five-axis machining, and the maximum precision can reach 0.01 mm.

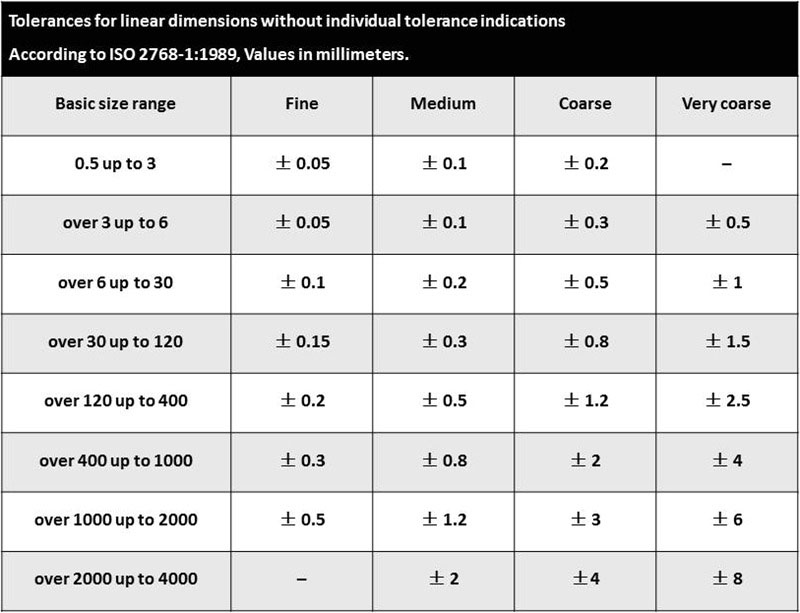

Need to achieve ±0.01mm accuracy or higher tight tolerances? MFG

HUBS will be your best manufacturing partner. Please do not hesitate

to send us drawings for a test quote anytime.

Our strong in-house production capabilities can ensure that you receive exactly the finished part you need

24 hours prompt response, 4-24 hours for quotation, 5-7 days for prototype

Complete testing equipment; Issue test report for each batch of parts before shipment

Flexible transportation methods (support DHL, FedEx, UPS, air or sea); Production progress updated at any time