ABS (Acrylonitrile Butadiene Styrene) is one of the most commonly used thermoplastics in the manufacturing industry. It is a versatile material that can be molded into different shapes and sizes, making it an ideal choice for a wide range of applications. As a mechanical engineer, you are likely to come across ABS in your daily work, making it crucial to know its properties, benefits, and limitations. In this blog post, we will discuss ABS material in detail to help you understand its usefulness and how to work with it.

Properties of ABS Material

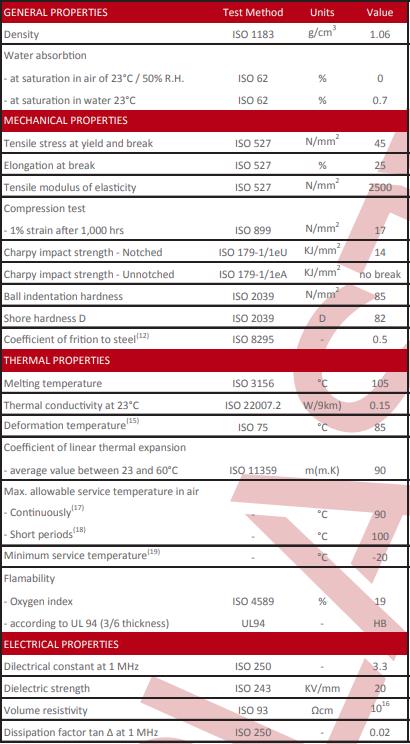

ABS is a tough and rigid plastic that has excellent impact resistance, making it the perfect choice for parts that are subjected to mechanical stress. It has a high tensile strength, making it ideal for use in applications that require load-bearing capabilities. ABS material is chemical resistant, heat resistant, and has a relatively low coefficient of thermal expansion. It is also a good electrical insulator and has good dimensional stability.

Benefits of ABS Material

One of the main benefits of ABS material is its versatility. It can be colored, textured, and painted, allowing you to create parts that match your requirements. ABS is easy to process, making it an affordable choice for a wide range of applications. It is also environmentally friendly and can be recycled, reducing waste and promoting sustainability.

Limitations of ABS Material

ABS is not suitable for use in high-temperature environments as it can deform at temperatures above 80°C. It is also susceptible to UV radiation, which can cause it to degrade over time, especially when exposed to sunlight. ABS can be challenging to bond, and it requires specialized adhesives or welding techniques.

Applications of ABS Material

ABS material is used in a broad range of applications, including automotive parts, toys, luggage, household appliances, and electronics. Its high impact resistance and excellent strength make it an ideal choice for parts that require durability. It is also used in the medical industry to manufacture equipment and instruments.

Working with ABS Material

When working with ABS, it is crucial to choose the right processing technique. ABS material can be injection molded or extruded, depending on the application. It is also essential to use the right temperature and pressure during processing to prevent deformation and warping. To bond ABS parts, you can use solvent cement or mechanical fastening techniques.

In conclusion, ABS is an incredibly versatile and useful material that is widely used in the manufacturing industry. As a mechanical engineer, it is crucial to understand the properties, limitations, and benefits of ABS material to determine when best to apply it in your projects. By knowing how to work with ABS, you can create complex parts that meet your requirements and your client’s needs. Understanding the properties and applications of ABS will help you expand your expertise in the field of mechanical engineering.